Ambala Unit 1, located in Ambala, Haryana, India, manufactures plant protection and plant nutrition products. Currently transitioning to solely produce plant nutrition products, the unit spans 2,466 square meters and is equipped with rotating blenders, spray vessels, conveyors, and filling machines. Accredited by DNV – Business Assurance, Ambala Unit 1 holds ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 quality, environmental, and occupational health and safety management systems.

Ambala Unit 2

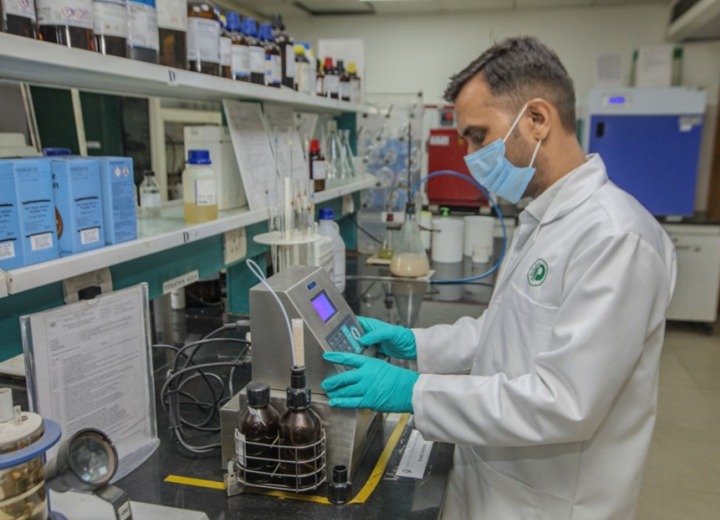

Ambala Unit 2, located in Ambala, Haryana, India, manufactures plant protection products. Spanning 8,678 square meters, it has the necessary plant and machinery to produce various formulations, including large stainless steel mixing and holding vessels, head auto-filling, auto-capping, induction sealing, auto-labeling, and steam heated shrink wrapping machines. The unit also houses seven auto-form, fill, and seal powder and water dispersible granules and granules packing machines. Ambala Unit 2 is accredited with ISO/IEC 17025:2017, ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 by DNV – Business Assurance.

Vadodara Unit

Vadodara Unit, located in Vadodara, Gujarat, India, manufactures plant protection products. Spanning 7,047 square meters, it has the necessary plant and machinery to produce various formulations, including auto-liquid filling, induction sealing, labelling, and shrink-wrapping machines with dust collection systems to minimize environmental release.

Leeds India Unit

Leeds Unit, based in Ambala, Haryana, India, manufactures plant protection products, including liquid plant protection products. Spanning 6,806 square meters, it has the necessary plant and machinery to produce various formulations, including batch processing vessels, auto-filling, and labelling machines. Accredited by DNV – Business Assurance, Leeds Unit holds ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 quality, environmental, and occupational health and safety management systems.

Cuddalore Unit

Cuddalore Unit, located in Cuddalore, Tamil Nadu, India, manufactures various Technicals. Spanning 6,350 square meters, it is equipped with plant and machinery for glass lined reactors, stainless steel reactors, autoclave pressure vessels, centrifuges, agitated nutsche filters, and ejectors. The unit also houses an effluent treatment plant with multiple effect evaporators, reverse osmosis units, and an agitated thin film evaporator, certified for ‘zero liquid discharge’. DNV – Business Assurance has accredited the unit with ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 standards.